Industrial product history system

During the production process, have you encountered the following problems?

Problems cannot be immediately located during the production process

Problems occur during the production process, but you are always the last to know?

Quality control is not precise enough

Want to reduce the defective rate during random inspections, but don’t know where to start?

Difficulties in generating inspection reports

Foreign manufacturers are paying more and more attention to product-related reports. What should we do?

Industrial product history system

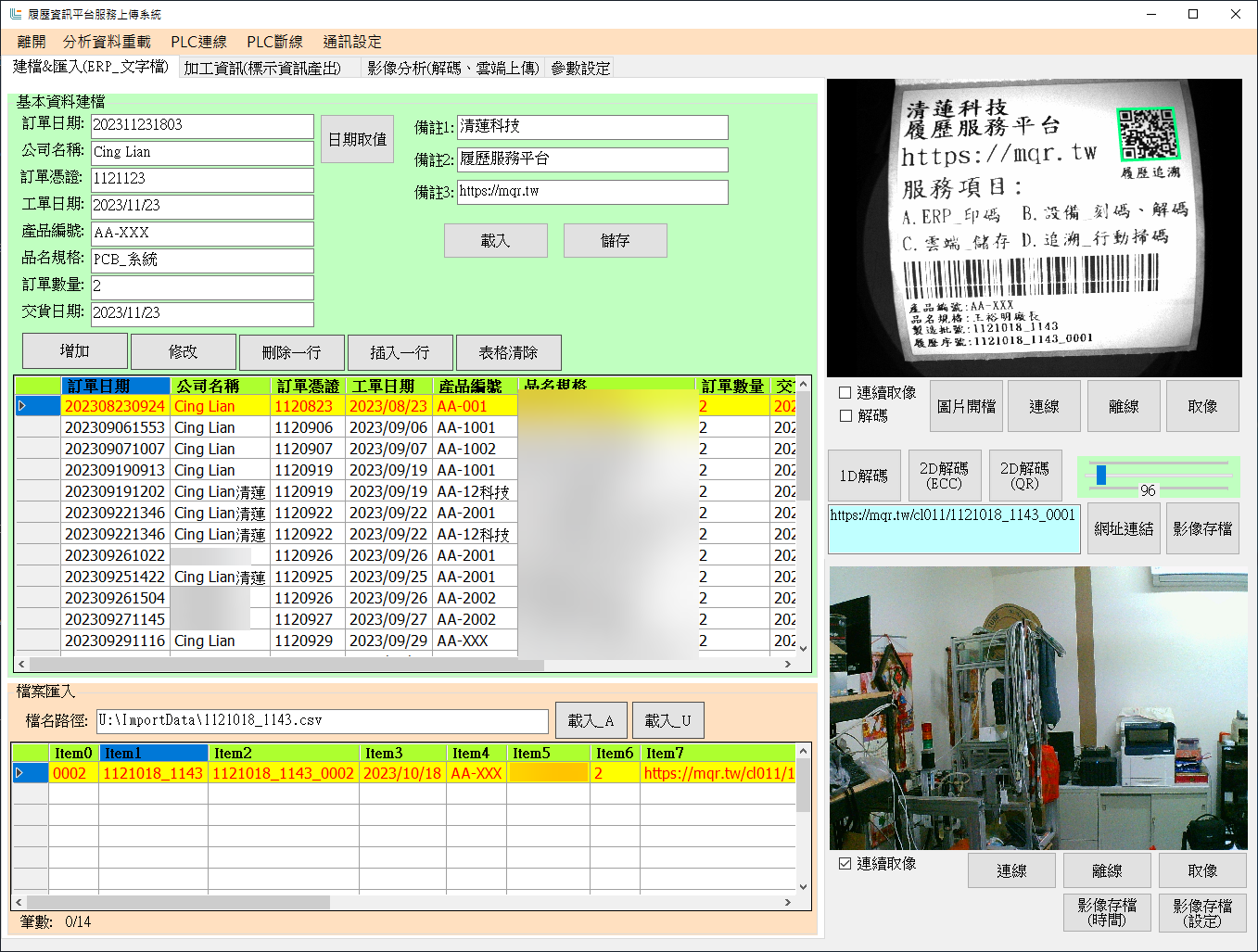

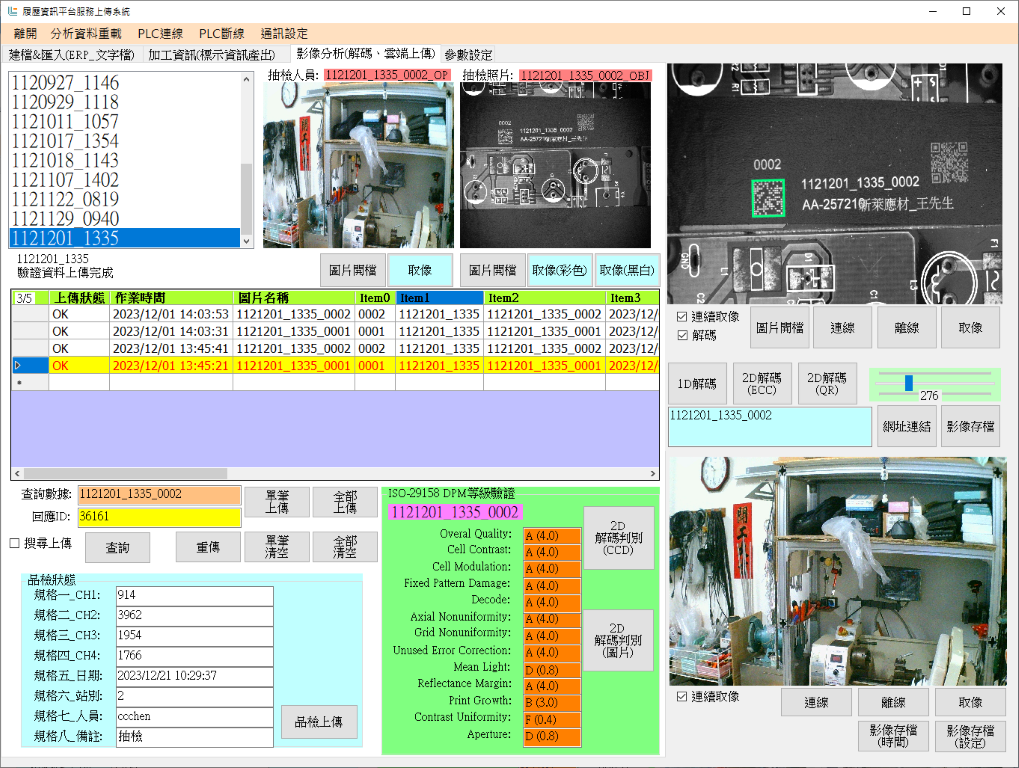

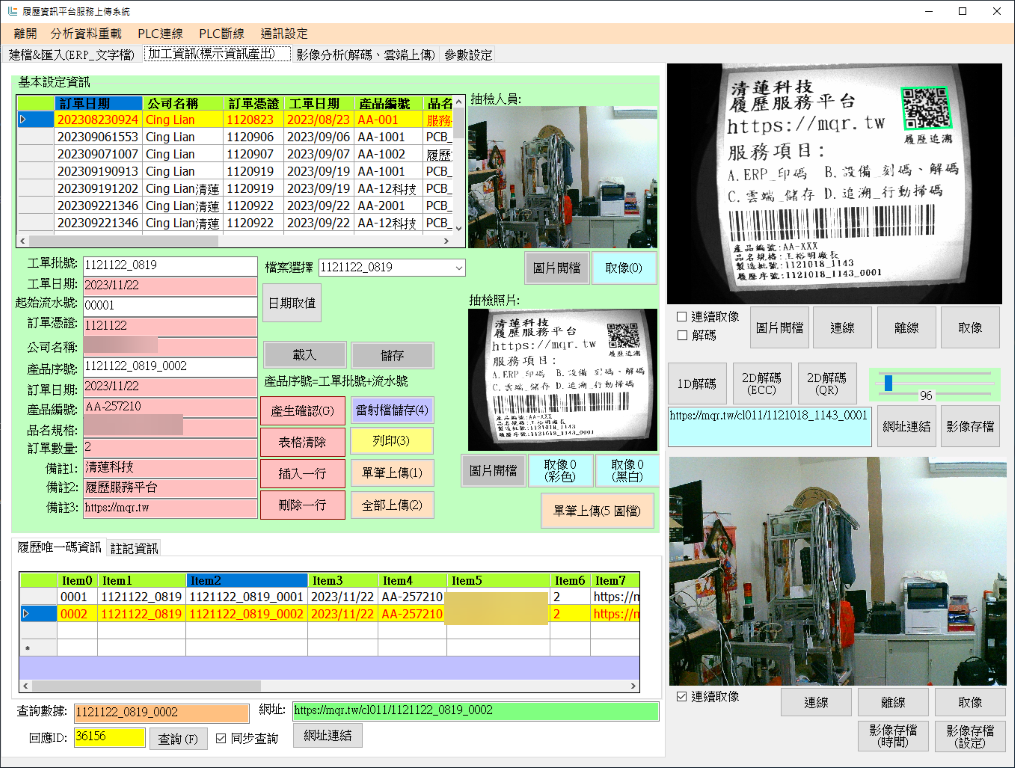

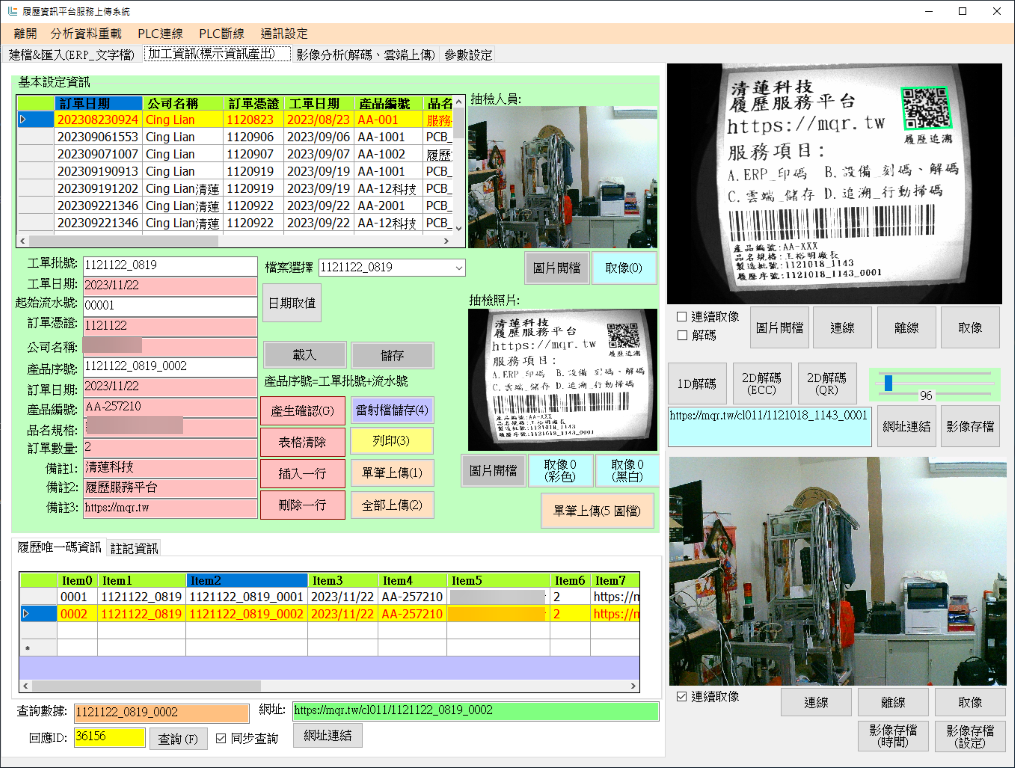

After monitoring on the production line, the data will be uploaded to the database in real time. Whether your production line has a single station or multiple stations, it can be integrated into a production report specific to the product.

Instantly know product process information

Through real-time uploading to the database, producers or on-duty personnel can directly obtain information about the product.

Unique production reports

The fields and display content of the resume system can be customized and the corresponding format selected to create your own production report.

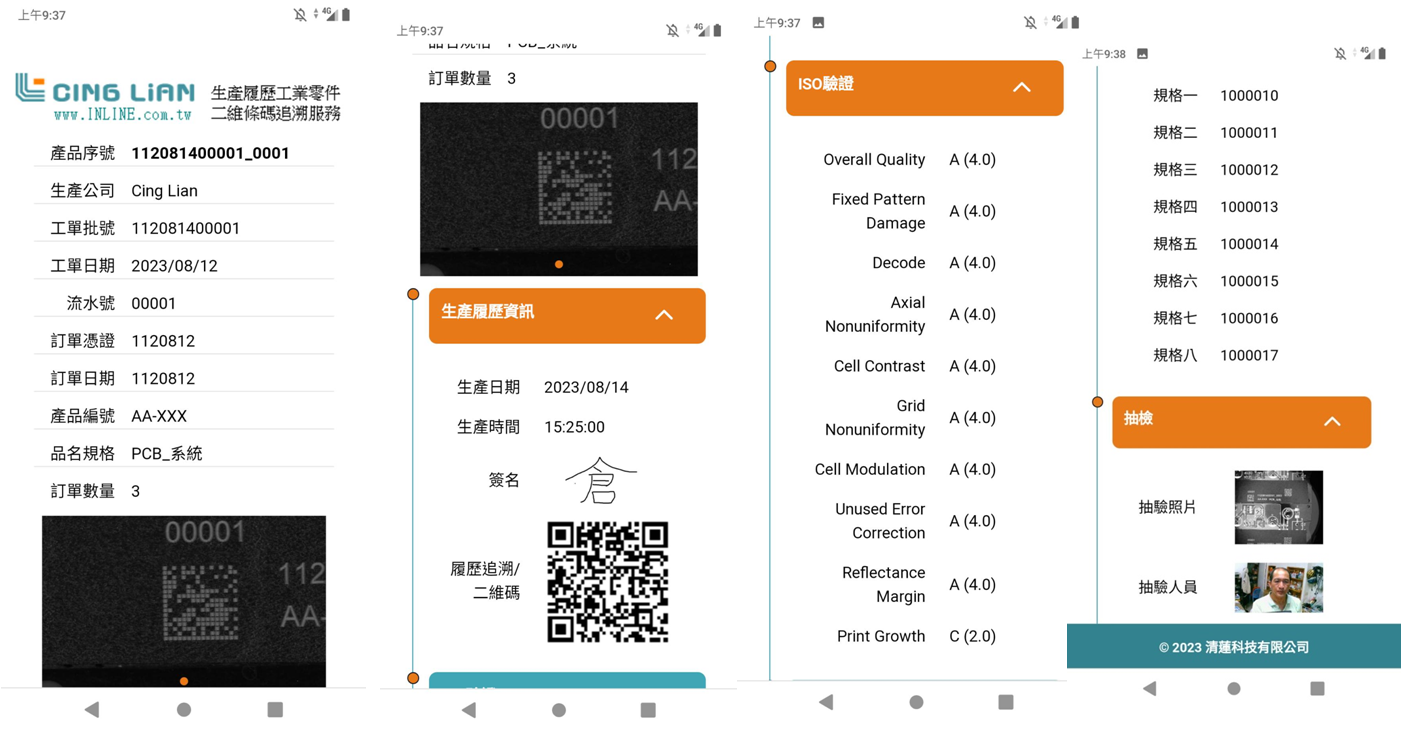

RWD screen adjustment

With the popularity of mobile devices, we also provide layouts adapted to mobile devices so that you can read them easily on different devices.

Four steps of resume

From product history generation to traceability, it only takes four simple steps

ERP printing form (printing)

Generate production work orders using ERP or supported data formats

Material marking (engraving, decoding)

Use laser engraving to print a unique QRcode on the product

Cloud Record

When you finish production, the data will be sent to the cloud immediately

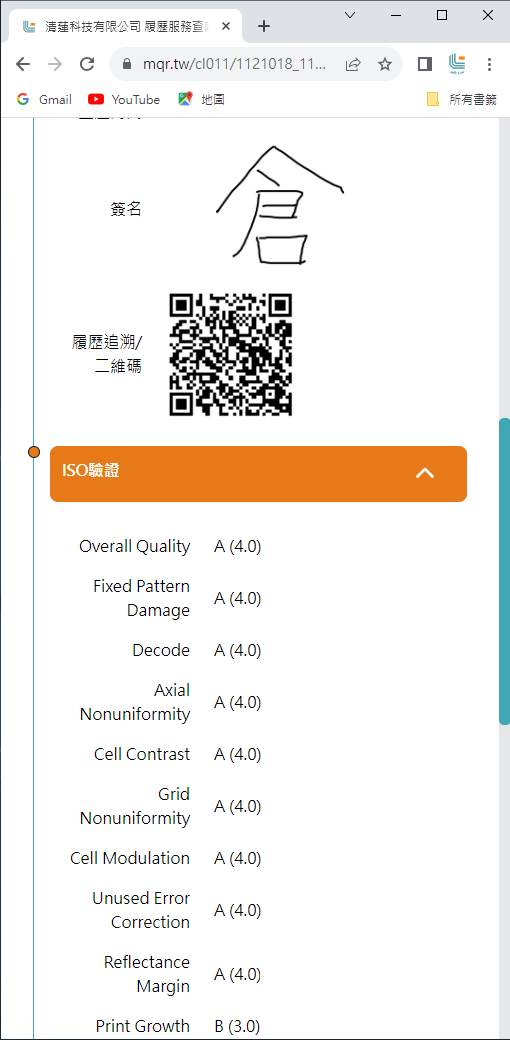

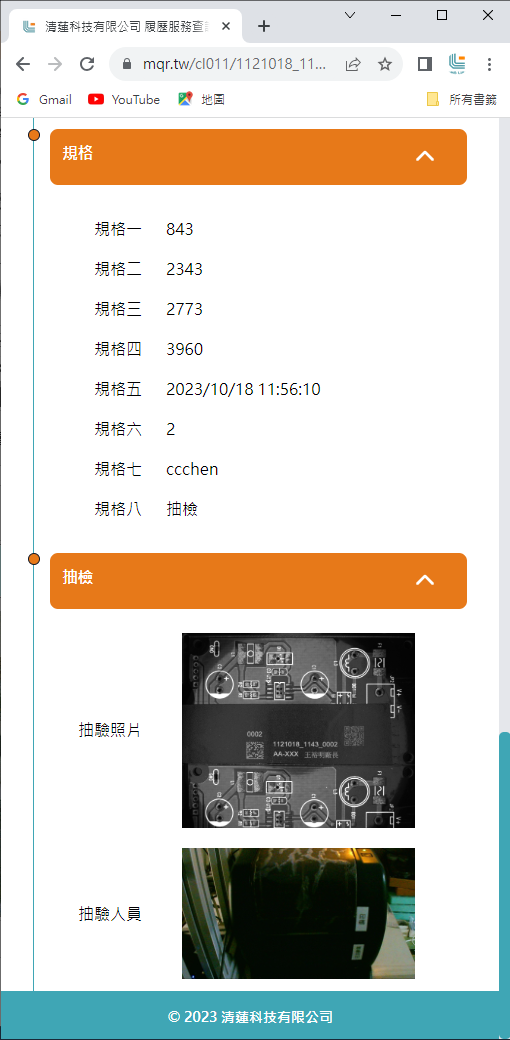

Traceback query (scan QR code)

If you want to know the process of a product on the production line, the footprint of the product will appear as soon as you scan the QRCODE

Process

Document

Manufacture

Record

Production History

What the resume system can do

In line with international major manufacturers

Quick arrangement of personnel training

Production problems and solution suggestions

Quick response decision-making internally and externally regarding product quality

Fast response to customer complaints about product information

Who can use the resume system

Incoming and outgoing warehouse data label management

Processing station work item specifications and logo marking

ERP system order data concatenation, item identification code is unique

End users are required to submit product reports and online inquiries

Concatenation of front and back data in the cloud system

System display

Try to scan the QRCODE below

If you are interested in this theme, contact us for more information