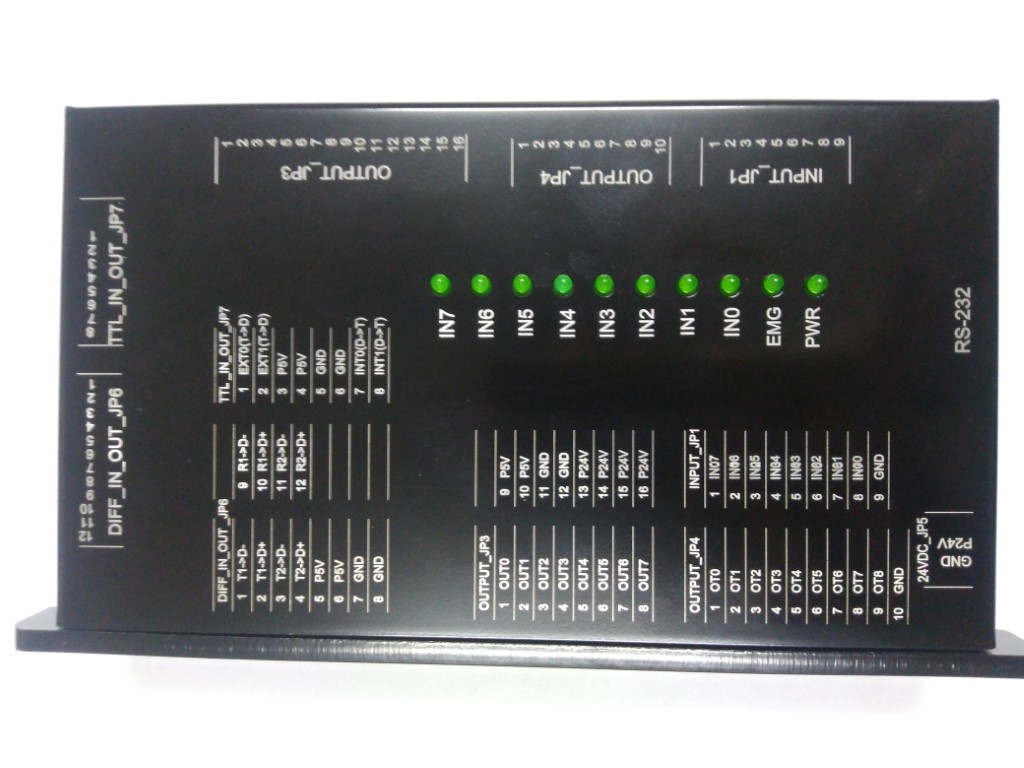

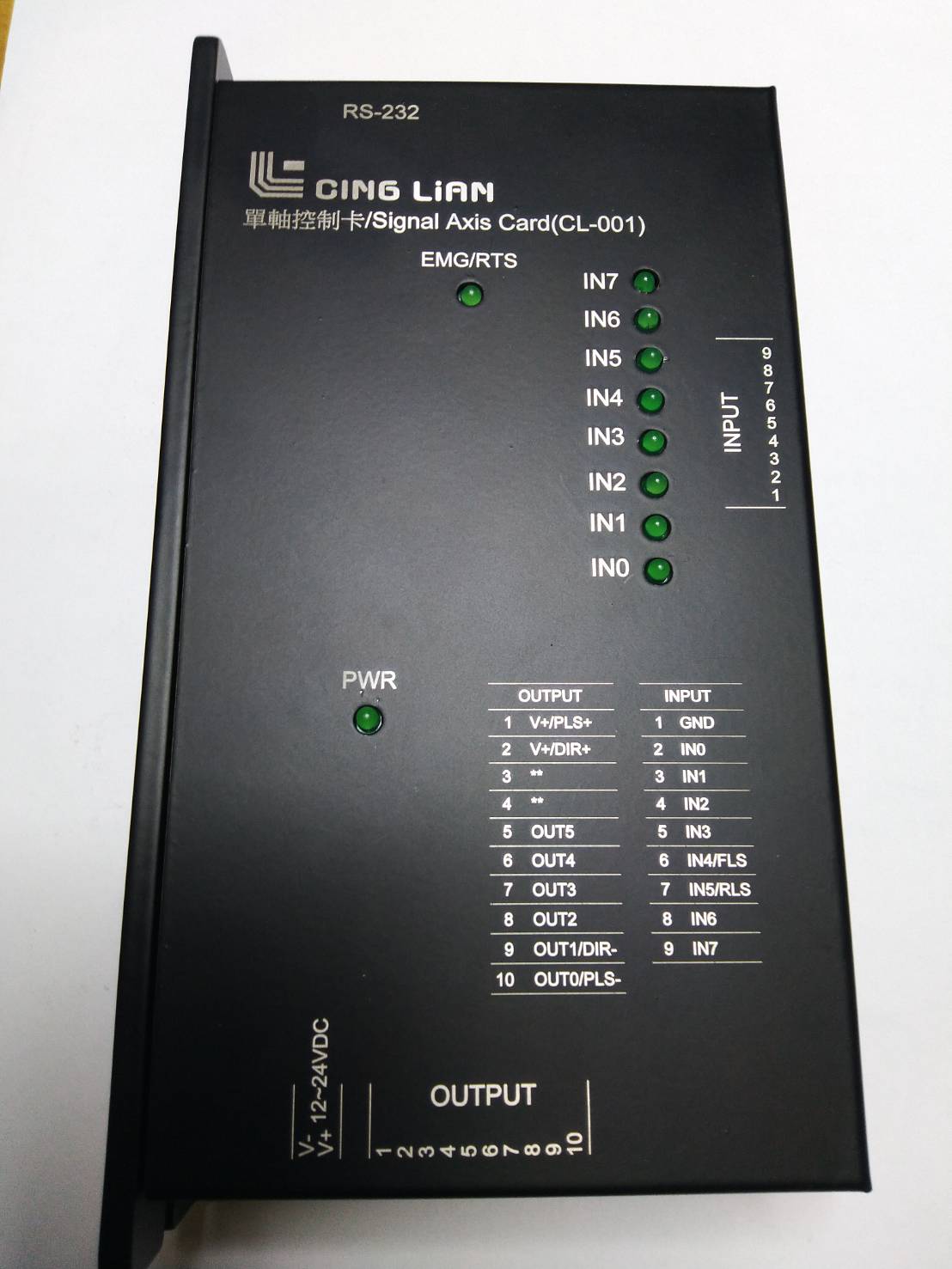

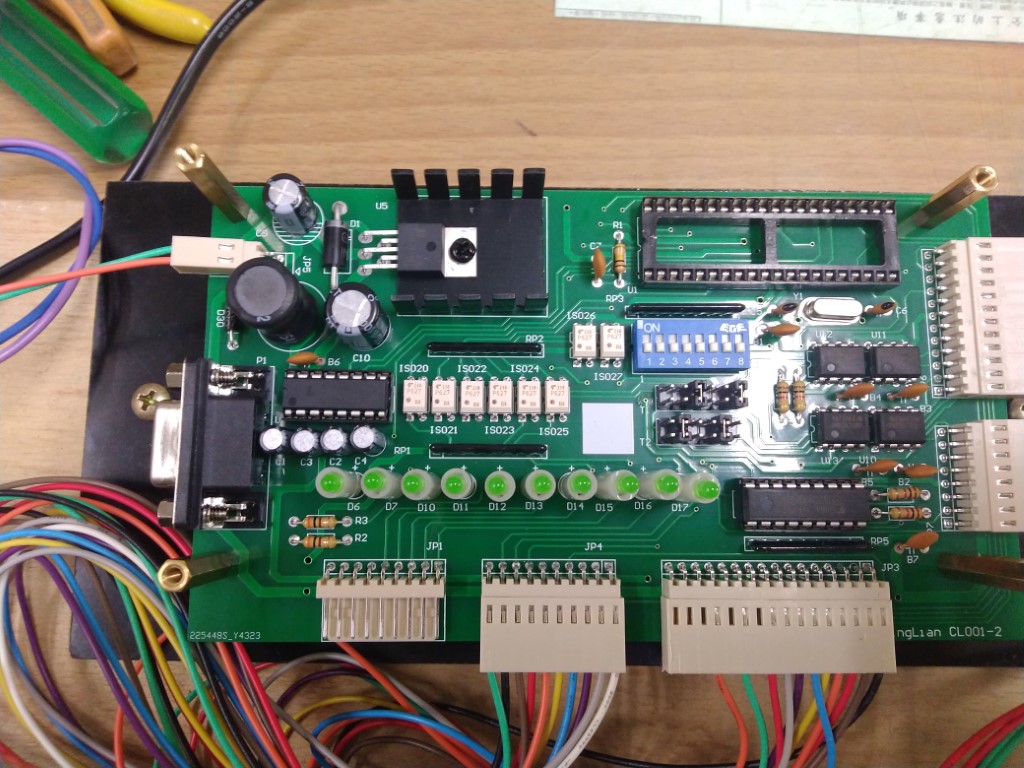

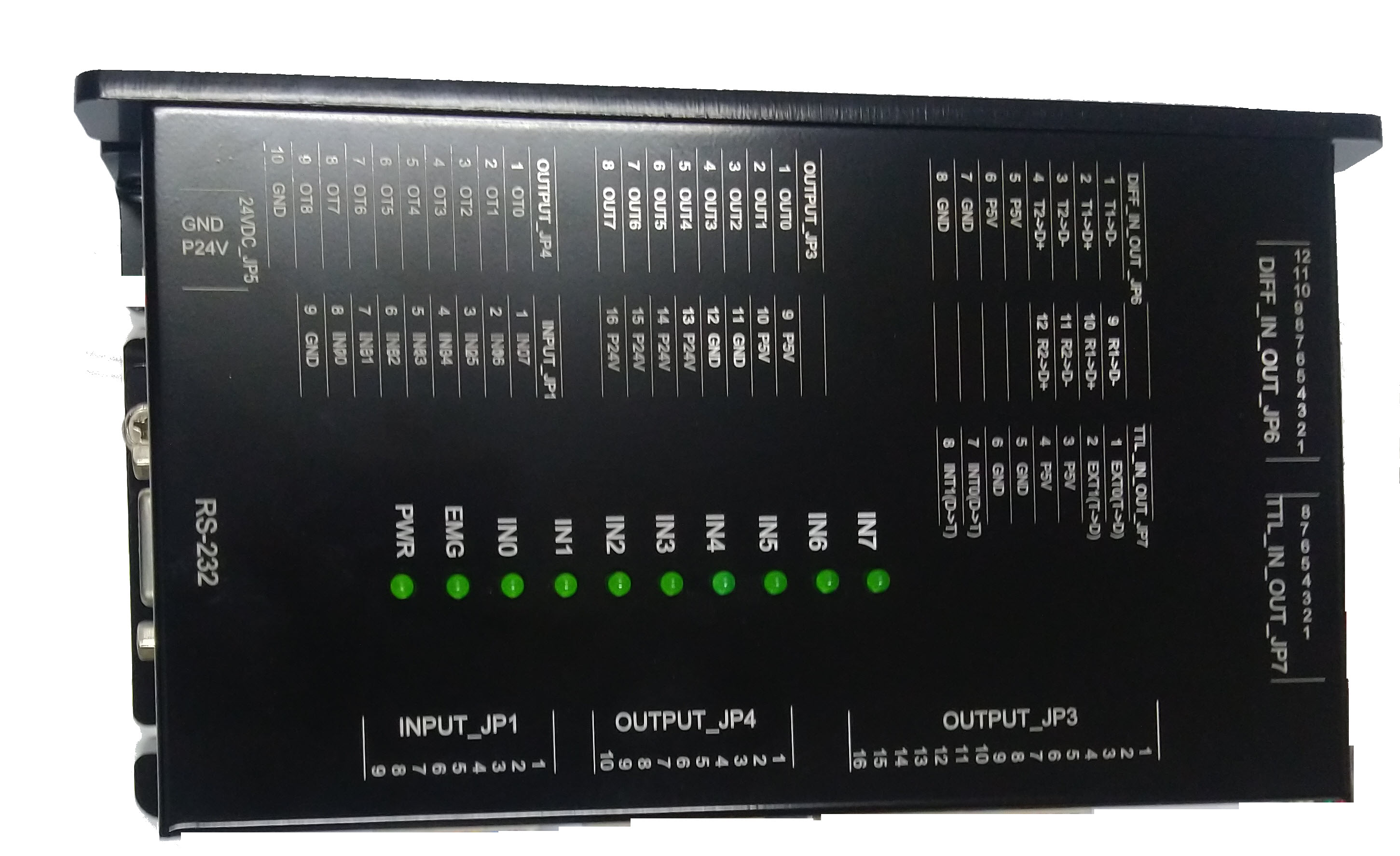

Hybrid control circuit board

CL001

Hybrid control circuit board

The hybrid control circuit board is a product with high integration and superior performance. It achieves multi-functional input and output and high-efficiency power management. Streamlined design, suitable for various application scenarios, providing stable and reliable control solutions for your electronic devices.

If the equipment specifications are different from your needs contact us for more information